AtoB1 in the icc profile specifies, with colorimetric rendering intent, the required conversion for device data (RGB or CMKY) to PCS data (Lab, typically). The information related to the transformation is derived solely from the characteristic data gathered during the profiling process and the implementation is pretty unknown to the end user. The accuracy of the employed technique will greatly determine the profile soft proofing capability.

Methodology

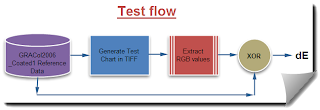

The same set of measured data for creating of the printer icc profiles with PM5 and MP, was used. The 120-patch test charts were generated for each profile, measurements were compared with the reference data.

1) Gamutvision

By setting both the input (Profile 1 or 3) and output (profile 2 & 4) to the same printer profile, the accuracy of the conversion can be thus tested.

a) Firstly, the test image was read according to the input file (the printer profile under test). In effect, the PCS output at this stage is the PCS data for the printer.

b) The input image is then mapped to to the output image according to the selected rendering intent. As the input profile is the same as output profile, no actual conversion should be taken place. Setting to either relative or absolute intents does not make any difference as the same conversion LUT table is used, BtoA1, I supposed.

In actual fact, above test is very similar to the round-trip test. (identical test?)

|

| with built-in 24 checker image |

|

| with 120 test patches |

|

| with 1617 test patches |

2) ColorThink Pro 3:

Evaluate Profile Proofing

|

| with CTP3, 120 test patches |

3) Hard Proofing

The best way to test a profile is to carry out a test print with the profile. It reflects the overall performance of the profile quality, and no way that we can test only the soft proofing portion of the printer profile.

References:

Evaluate Profile Proofing by ColorThink Pro 3

Using Gamutvision